Choosing between Fatra and Torch on:

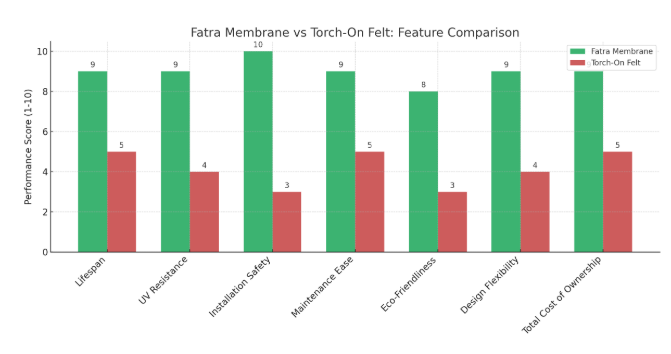

Choosing between Fatra flat roof membranes and torch-on felt roofing depends on several factors including performance, longevity, installation safety, environmental impact, and cost-effectiveness. Here’s a detailed comparison highlighting why Fatra flat roof membrane is generally considered a superior product over traditional torch-on felt:

Material Technology & Performance

Fatra Membrane:

Made from PVC (polyvinyl chloride) or TPO, which are high-performance synthetic materials.

Offers high UV resistance, chemical resistance, and dimensional stability.

Typically reinforced with polyester mesh or glass fleece for additional strength.

Torch-On Felt:

Made from bitumen-based materials layered with mineral surfaces.

Bitumen can degrade over time due to UV exposure, leading to cracks and leaks.

Verdict: Fatra membranes are far more durable and resistant to weathering, particularly UV degradation.

Lifespan and Durability

Fatra Membrane:

Typical lifespan of 30–40+ years with minimal maintenance.

Joints are heat-welded, forming a homogeneous and watertight seam.

Torch-On Felt:

Lifespan is typically 10–20 years, depending on maintenance.

Vulnerable to cracking and blistering over time.

Verdict: Fatra offers longer-lasting and more reliable protection.

Installation Safety

Fatra Membrane:

Installed using cold application methods – either mechanically fixed, bonded, or ballasted.

No open flames, reducing fire risks significantly.

Torch-On Felt:

Requires open flame torches for application.

Higher risk of fire hazards, especially near timber structures or insulation.

Verdict: Fatra is far safer to install, particularly in urban or occupied environments.

Maintenance and Repair

Fatra Membrane:

Easy to inspect and repair.

Patches can be heat-welded onto existing membrane seamlessly.

Torch-On Felt:

Repairs can be trickier and often require partial re-roofing.

Prone to moisture ingress if the felt is compromised.

Verdict: Fatra membranes offer easier and more effective maintenance.

Environmental Impact

Fatra Membrane:

Often manufactured with recyclable materials and lower VOC emissions.

Can be installed as part of green roofing systems (e.g., Fatra’s green roof-compatible options).

Torch-On Felt:

Bitumen is a petroleum product and less eco-friendly.

Installation process can produce harmful fumes.

Verdict: Fatra membranes are generally more environmentally friendly.

Aesthetics & Versatility

Fatra Membrane:

Available in various colors and finishes.

Can accommodate complex roof shapes and detailing.

Torch-On Felt:

Limited aesthetic appeal.

More difficult to install neatly around penetrations and upstands.

Verdict: Fatra offers greater design flexibility and cleaner appearance.

Cost Consideration

Fatra Membrane:

Higher upfront cost, but lower lifecycle cost due to longevity and reduced maintenance.

Torch-On Felt:

Cheaper initially, but often results in higher long-term costs due to repairs and shorter lifespan.

Verdict: Fatra is more cost-effective in the long term

Conclusion: Why Fatra is Better

Conclusion: Why Fatra is Better